|

How

to make a leather handled knife

The leather pile should be compressed in the clamp for 3 days to ensure

that it compacts evenly. When you remove the clamp, you need to set the

rivet. The length of tang that should be left above the rivet surface

is equal to its diameter. This will always make a good rivet. Tap

accurately with the hammer until the metal deforms to make a strong rivet.

It might take 5 minutes, but it will work. Don’t rush it.

|

|

A belt sander makes shaping very quick and easy, but leather knives are

easy to shape by hand, because the material is still quite soft. I always

let the sander scorch the handle at the beginning of shaping. The heat

hardens the leather and the scorching is only on the surface and is easily

removed with further sanding.

|

|

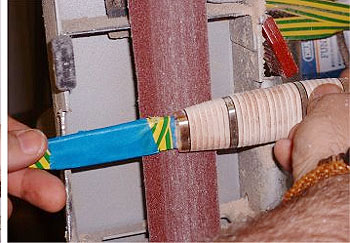

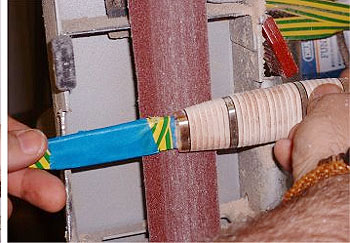

Shaping should always be completed by hand with strips of abrasive

as shown. This ensures a smooth and even surface. Some leather grease

can be used to lubricate the surface of the leather. If you want a

hard glossy surface, treat the leather with super-glue then sand it

smooth with grits from 240 to 800, then treat with CCL knife handle

polish. Birch bark handled knives can be finished with CCL oil without

the need for superglue first.

|

|

y favourite more traditional finish is much slower than that. You need

good quality soft leather grease such as Gold Quality Laederfedt and some

gum tragacanth will help achieve a tough smooth finish. Sand to 240 grit

using a light action. Now rub some grease into the leather with your

fingertips, then leave it for half an hour. Wipe off any excess, then

sand lightly with 320 grit abrasive. Rub in some more grease, wait half

an hour and sand with 400grit abrasive. Repeat this for 600, 800 and 1000

grits, then substitute a drop of gum tragacanth in place of the grease.

Rub this in very hard with vinyl or latex gloved fingertips

(helps the polishing). Leave for half an hour, then sand with 1200 grit

abrasive. Do the same for 1500 grit, then leave it overnight. The next day,

rub in some leather grease very gently and sand with 2000 grit abrasive

and repeat for 2500 grit. If you have a buffing machine, you can buff the

handle with pure bees-wax after the gum tragacanth stage.

|

|

You can do a lot with stacked leather if it is compressed properly.

The knife with the reconstituted jade spacer and butt cap has been

used heavily for several years, with no problems for the handle,

the rather deep guard is completely solid. That is more than you

can say for the blade though. I don’t recommend the use of reconstituted

stone spacers in leather handled knives. The dust produced by sanding

clings to the leather fibres. This knife has a strong rivet washer

underneath the jade cap. The knife at the bottom is interesting because

it was made the old-fashioned way with no glue at all; it is held

together entirely by the strength of the rivet.

You might like to try that for a later project.

|