|

How

to make a leather handled knife

The leather you use should ideally be 4-4.5mm thick, I usually use

thick shoulder leather. It will be compressed to some extent, so

you don’t want it to be too thin. It is best to sand off the glossy

side of the leather before you make it in to a handle. This isn’t

essential, but it improves the line of the finished handle.

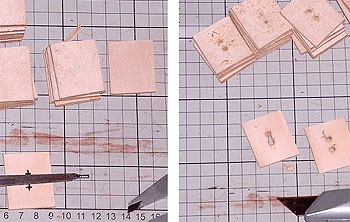

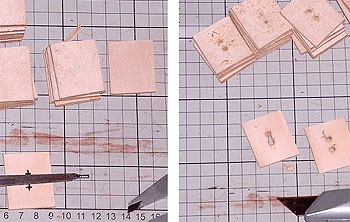

Cut the leather into small rectangles of about 35mm x 25mm.

Draw in the centreline and use the tang itself

(or a calliper measurement) to mark the position of the hole, so

that it falls 1mm or so either side of the top and bottom faces

of the tang (Fig 6). Each piece of leather should be made to

fit the tang in the position that it will sit.

|

|

The tang on this knife was just over 3mm thick, so I used a 4mm

drill bit to punch in holes at the top and bottom of the proposed

slot, then cut the remainder out with a sharp knife. If you do

this sloppily, just drilling a big hole in the middle of them all,

and pushing them on you will regret it later, when the sections

start to slip and rotate. This is a 35 piece handle, each section

requires careful attention. You only need one piece to be out of

line or twisted around to cause problems. As soon as you have

marked the leather pieces for drilling, it is important to develop

a system to keep them in order. After drilling and cutting, I gently

buzz them with a barrel sander to smooth the faces.

|

|

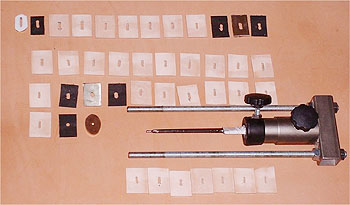

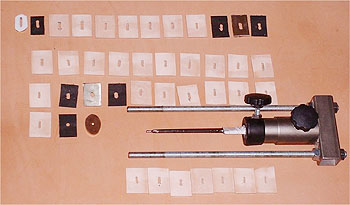

Make sure that you test assemble the handle several times under

tension in your clamp. I used the clamp sold here in the tools

section, but you could make your own, look at the Saami knife

tutorial for ideas. If you are using spacers, make them symmetrical,

in other words, if you have 8 leather pieces between the bolster

and first spacer, there should be the same number between the back

spacer and the butt cap. The small pile of spares is are important

for two reasons: Firstly because you are likely to mess up one or

two pieces during the gluing process, throw that piece away, because

it is probably covered with epoxy and will make a mess. Move on to

the next piece, it will still fit and you can use pieces from the

spares pile to fill in at the end. Secondly, these “spares” will

be glued together to form your practice block. This is an absolutely

essential part of the process.

|

|

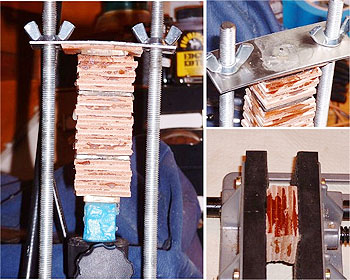

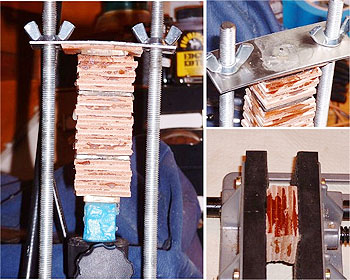

Before you do the final assembly, tape the blade and grease the top

of the blade and the front of the bolster with Vaseline; this prevents

the epoxy from getting where you don’t want it! Assemble the handle

one piece at a time, applying only a small smear of 24hr epoxy all

around the skin side of the leather, then press it down firmly on

to the pile. Don’t saturate the leather with epoxy, just lightly

glue the pieces together and to the tang. Fix the top clamp bar

in place and compress the pile. Don’t try to squeeze the life out

of it, you should compress the pile down about two or three thicknesses

of leather. Fill the top hole with Vaseline, again this prevents any

epoxy that might squeeze out from causing grief. Very little glue

should come out under compression, this is not a messy process if you

do it properly. The spare pieces of leather should be clamped to make

your practice block for finishing.

|

|

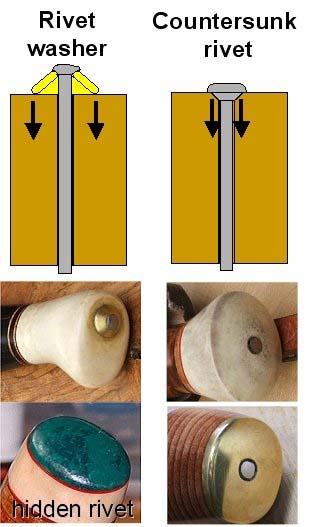

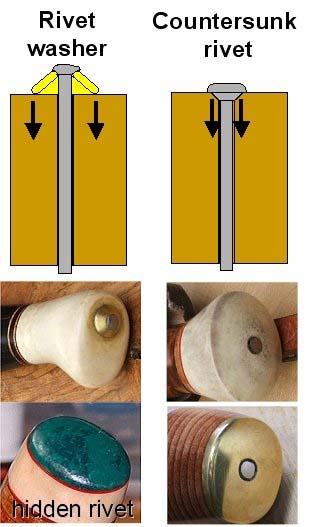

You will need to rivet the knife tang to the butt cap. Rivet washers

are the easiest to set and make the strongest form of rivet, because

they press over a greater surface area. They are essential if you are

riveting into soft antler marrow, but rosencrans, any decent hardwood

or metal will take a simple rivet, or a flush countersunk rivet. For

a thick metal butt-cap, I would usually countersink the rivet, but in

this project I am using a rivet washer to show how it works. Both are

formed in the same way by even tapping with the round face of a ball

pein hammer directly to the centre of the tang-end. If you do use a

simple rivet, countersink the butt-cap slightly.

|